Electromagnetic flowmeter

The company's electromagnetic flowmeter in accordance with the Chinese national standard "JG-1033-2007 Electromagnetic Flowmeter" implementation, is a measurement of conductive medium volume flow of the induction instrument, in the field monitoring display at the same time, can output the standard current signal, for recording, adjustment, control use, to achieve automatic control detection, and can achieve long-distance transmission of signals. Can be widely used in water, chemical, coal, environmental protection, textile, metallurgy, paper and other industries in the flow measurement of conductive liquid.

Key words:

Classification:

Telephone:

E-mail:

Electromagnetic flowmeter

Overview

The company's electromagnetic flowmeter in accordance with the Chinese national standard "JG-1033-2007 Electromagnetic Flowmeter" implementation, is a measurement of conductive medium volume flow of the induction instrument, in the field monitoring display at the same time, can output the standard current signal, for recording, adjustment, control use, to achieve automatic control detection, and can achieve long-distance transmission of signals. Can be widely used in water, chemical, coal, environmental protection, textile, metallurgy, paper and other industries in the flow measurement of conductive liquid.

Working principle

The electromagnetic flowmeter uses the principle of Faraday's induction law, that is, when a conductive object cuts the magnetic lines of force in a magnetic field, an induced electromotive force is generated in the conductor. Its induced electromotive force E is:

E = KBdV

Flow Q is:

Q = 3600 × v×s

Where:

K-instrument coefficient

B- magnetic induction intensity (T)

D-electrode spacing (m)

V fluid average velocity (m/s)

S-inner cross-sectional area of duct (m²)

When measuring the flow rate, the conductive liquid flows through a magnetic field perpendicular to the flow direction at a flow rate V. The flow of the conductive liquid induces a voltage proportional to the average flow rate, and the induced voltage signal is detected by the electrode in direct contact with the liquid. For the same flowmeter S, B, d are constant, so the flow rate is proportional to the magnitude of the induced electromotive force E (or flow velocity V).

Product Features

1. There are no moving parts in the measuring tube, which is convenient for maintenance and management; there are no blocking parts, so there is no pressure loss.

2. The minimum conductivity of the measured liquid is ≥ 30 μs/cm, and with various lining materials, it can be applied to measure the flow of various acids, alkalis, salt solutions, mud, pulp and other media.

3. The flow measurement is not affected by the density, viscosity and temperature of the fluid. Pressure and conductivity changes affect the sensor sensing voltage signal.

4. It has a linear relationship with the average flow rate, and the measurement accuracy is high.

5. Reasonable selection of lining and electrode materials can achieve good corrosion resistance and wear resistance.

6. Low frequency rectangular wave excitation, not affected by the frequency and the field of various stray interference, stable and reliable work.

7. Not affected by the direction of the fluid, both forward and reverse can be accurately measured.

8. The range ratio is 1:30(0.5m/s-15m/s), and the full-scale flow rate is wide.

9. Chinese character LCD backlight display, can modify parameters online, simple and convenient operation. 10. With empty pipe measurement, alarm function, and can adapt to different fluid medium.

Complete machine and sensor technical data

|

Nominal diameter (mm) |

3/6/10/15/20/25/32/40/50/65/80/100/125/150/200/250/300/350/400/450/500/600/700/800/900/1000/1200/1400/1600/1800/2000.. |

||||

|

Maximum flow rate |

15m/s |

||||

|

Precision |

DN15-DN600 |

Indication: ± 0.5 (flow velocity ≥ 1 m/s);± 3 mm/s (flow velocity ≤ 1 m/s) |

|||

|

DN70-DN3000 |

Indication: ± 0.5 (flow rate ≥ 0.8 m/s);± 4 mm/s (flow rate ≤ 10.8 m/s) |

||||

|

Nominal pressure |

4.0MPa |

1.6MPa |

1.0MPa |

0.6MPa |

6.3/10MPa |

|

DN15-DN50 |

DN65-DN250 |

DN300-DN1000 |

DN1000-DN3000 |

Special Orders |

|

|

Ambient temperature |

Sensor |

-25 ℃- 60 ℃ |

|||

|

Converter and integrated type |

-10 ℃- 60 ℃ |

||||

|

lining material |

Polytetrafluoroethylene, polychloroprene rubber, polyurethane, polyethylene propylene (F46) |

||||

|

Maximum fluid temperature |

One-piece type |

70℃ |

|||

|

Separation type |

Polyfluorobutadiene rubber lining |

60 ℃;120 ℃ (indicated when ordering) |

|||

|

Polyurethane lining |

50℃ |

||||

|

Teflon lining |

100 ℃;150 ℃ (indicated when ordering) |

||||

|

Perfluoroethylene propylene (F46) |

|||||

|

electrode material |

Stainless steel, Hastelloy B, Titanium, Tantalum, Platinum/Iridium alloy |

||||

|

electrode scraper |

Customizable |

||||

|

Enclosure protection |

DN15-DN3000 Separate Rubber or Polyurethane Lined Sensors |

IP65 or 1P68 |

|||

|

Spacing (Split) |

Other Sensors, Integral Flow Meters and Parting Converter |

1P65 |

|||

|

Converter distance sensor is generally not more than 30m |

|||||

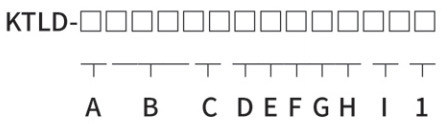

Product Model and Marking

A- installation form (* Y-integrated, * F-split)

B- Nominal diameter (mm)

C nominal pressure (MPa)(* 06-0.6,* 10-1.0,* 16-1.6,* 40-4.0,* XX special order)

D-lining material (* 1-polytetrafluoroethylene (F4),* 2-polychloroprene rubber, * 3-polyurethane, * 4-polytetrafluoroethylene propylene (F46)* 5-PFA)

E-electrode material (* G-stainless steel, * B- Hastelloy B,* C- Hastelloy C,* I-titanium, * A- tantalum, * Y-platinum iridium alloy, * W-stainless steel coated with tungsten carbide)

F-protection class (* 1-IP65,* 2-IP68 IP65 (I. e. sensor IP68 converter IP65),* 3-IP67 IP65 (I. e. sensor IP67 converter IP65),* 4-submersible (I. e. sensor IP68 converter IP68))

G-Explosion-proof mark (* 0-None, * 1-Explosion-proof type)

H-connection mode (* F-flange connection, * S-thread connection, * K-chuck connection)

I-Power supply (* 1-3.6VDC,* 2-24VDC,* 3-220VAC,* 4-24VDC/220VAC dual supply)

J-output mode (* M-pulse output, * D-current output, * R-RS485,* Q-full function output, * T-cold/heat metering)

|

Encoding |

Path |

|

030 |

3 |

|

060 |

6 |

|

100 |

10 |

|

150 |

15 |

|

200 |

20 |

|

250 |

25 |

|

320 |

32 |

|

400 |

40 |

|

500 |

50 |

|

650 |

65 |

|

800 |

80 |

|

101 |

100 |

|

125 |

125 |

|

151 |

150 |

|

201 |

200 |

|

251 |

250 |

|

301 |

300 |

|

351 |

350 |

|

401 |

400 |

|

451 |

450 |

|

501 |

500 |

|

601 |

600 |

|

701 |

700 |

|

801 |

800 |

|

901 |

900 |

|

102 |

1000 |

|

122 |

1200 |

|

142 |

1400 |

|

162 |

1600 |

|

182 |

1800 |

|

202 |

2000 |

|

222 |

2200 |

|

242 |

2400 |

|

262 |

2600 |

|

282 |

2800 |

|

302 |

3000 |

Electromagnetic Flowmeter Range Selection Table

|

Caliber (mm) |

Range (m³/h) |

||

|

10 |

0.02827-0.25 |

0.3-1.6 |

2.0-3.3921 |

|

15 |

0.0636-0.6 |

0.8-3.0 |

4.0-7.632 |

|

20 |

0.0636-0.6 |

1.2-5.0 |

6.0-13.6 |

|

25 |

0.176-1.6 |

2.0-8.0 |

10-21 |

|

32 |

0.2895-2.5 |

3.0-12 |

16-35 |

|

40 |

0.4524-4.0 |

5.0-20 |

25-45 |

|

50 |

0.707-6.0 |

8.0-40 |

50-85 |

|

65 |

1.195-10 |

12-60 |

80-143 |

|

80 |

1.81-16 |

20-120 |

160-217 |

|

100 |

2.83-25 |

30-160 |

200-339 |

|

125 |

4.42-40 |

50-250 |

300-530 |

|

150 |

6.36-60 |

80-400 |

500-763 |

|

200 |

11.3-100 |

120-600 |

800-1357 |

|

250 |

17.7-160 |

200-800 |

1000-2120 |

|

300 |

25.45-250 |

300-1200 |

1600-3054 |

|

350 |

34.6-300 |

400-1600 |

2000-4157 |

|

400 |

45.2-400 |

500-2000 |

2500-5429 |

|

450 |

57.3-500 |

600-2500 |

3000-6871 |

|

500 |

70.7-600 |

800-3000 |

4000-84823 |

|

600 |

102-800 |

1000-4000 |

5000-12216 |

|

700 |

139-1200 |

1600-5000 |

6000-16620 |

|

800 |

181-1600 |

2000-6000 |

8000-21720 |

|

900 |

229-1600 |

2000-8000 |

10000-27480 |

|

1000 |

283-2000 |

2500-10000 |

12000-33924 |

|

1200 |

407-2500 |

3000-12000 |

16000-48833 |

|

1400 |

554-3000 |

4000-16000 |

20000-66468 |

|

1600 |

723-4000 |

5000-20000 |

27000-86815 |

Factory display

Plant display 7

Plant display 8

Plant display 6

Plant display 5

Plant Display 4

Plant Display 9

Plant Exhibition 3

Plant display 2

Factory display

Honor Show

Exhibition style

Previous Page

Next Page

Previous Page

Liquid turbine flowmeter

Next Page

Related Products

Product Consulting

We will contact you within one working day. Please pay attention to your email.